Pipe Fitting

QS 24 FT 003

Flexible Rubber Joint, 20 Inch, 150 LB, NBR, One Ball Joint, Single Sphere Joint, Composed of Fabric Reinforced Rubber Parts and Lose Metal Flanges

QS 24 FT 002

Rubber Expansion Joint, 8 Inch, 150 LB, Face Sealed Rubber Joint, Material EPDM Joint, With Carbon Steel Flange B16.5 Coated with Zinc, Suitable for Water, Air, etc.

QS 23 FT 001

PTFE Lined Rubber Expansion Joint, 10 Inch, 150 LB, ANSI B16.5, Carbon Steel Flange with Zinc Coating, Maximum temperature 120 degrees Celsius

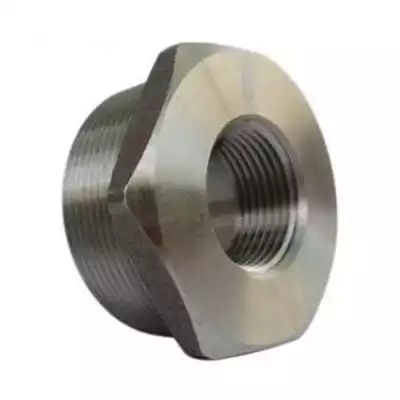

QS 23 PT 51

Hexagon Bushing, ASME B16 11, NPT, 2 Inch, Class 3000, ASTM A105, F304, F316, F304L, F316L, A182 F11/F22/F91, A182 F51.

QS 23 PT 49

90 Deg Elbow made by us are designed as per ANSI B16.9, they featured in BW Ends, material ASTM A234 WPB.

QS 23 PT 47

Hexagon Nipple as per BS3799, it featured NPT ends, design pressure 3000LB, material ASTM A105, size range 1/2 inch to 2 inch.

QS 23 PT 45

Half Coupling designed according to ANSI B16 11, 2 Inch, ASTM A105, SW and NPT ends are available, rating 3000LB.

QS 23 PT 43

Full Coupling designs as per ANSI B16.11, 2 inch, connection ends available are SW, NPT, pressure 3000LB, material ASTM A105.

QS 23 PT 41

Forged Cap designed as per ASME B36.10 for high pressure pipe line service, 2 inch, 3000LB, NPT end, Material ASTM A105.

Types

Butt welded fitting

45 deg. short radius elbow, 90 deg. short radius elbow, 180 deg. short radius elbow, 45 deg. elbow, 90 deg. elbow, 180 deg. elbow

Equal tee, reducing tee

Concentric reducer, eccentric reducer

Cross, equal cross, reducing cross

Half coupling, full coupling, reducing coupling

Cap, bend, barred tee, stub end, weldolet, sockolet, threadolet, hex. nipple, swage nipple, union, boss, hex. head bushing, plug, etc.

Processing

Butt welding and forging

Sizes

DN15, DN20, DN25, DN32, DN40, DN50, DN65, DN80, DN90, DN100, DN125,DN150, DN200, DN250, DN300, DN350, DN400, DN450, DN500, DN550, DN600, DN650, DN700, DN750, DN800, DN850, DN900, DN950, DN1000, DN1050, DN1100, DN1150, DN1200

OD21.3 mm, OD26.7 mm, OD33.4 mm, OD42.2 mm, OD48.3 mm, OD60.3 mm, OD73 mm, OD88.9 mm, OD101.6 mm, OD114.3 mm, OD141.3 mm, OD168.3 mm, OD219.1 mm, OD273.1 mm, OD323.9 mm, OD355.6 mm, OD406.4 mm, OD457.2 mm, OD508 mm, OD559 mm, OD610 mm, OD660 mm, OD711 mm, OD762 mm, OD813 mm, OD864 mm, OD914 mm, OD965 mm, OD1016 mm, OD1067 mm, OD1118 mm, OD1168 mm, OD1219 mm

1/2 Inch, 0.5 Inch, 3/4 Inch, 0.75 Inch, 1 Inch, 1-1/4 Inch, 1.25 Inch, 1-1/2 Inch, 1.5 Inch, 2 Inch, 2-1/2 Inch, 2.5 Inch, 3 Inch, 3-1/2 Inch, 3.5 Inch, 4 Inch, 5 Inch, 6 Inch, 8 Inch, 10 Inch, 12 Inch, 14 Inch, 16 Inch, 18 Inch, 20 Inch, 22 Inch, 24 Inch, 26 Inch, 28 Inch, 30 Inch, 32 Inch, 34 Inch, 36 Inch, 38 Inch, 40 Inch, 42 Inch, 44 Inch, 46 Inch, 48 Inch

Schedule or Wall Thickness

SCH 5, SCH 5S, SCH 10, SCH 20, SCH 30, SCH STD, SCH 40, SCH 60, SCH XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, SCH XXS

1.65mm, 2.11mm,2.41mm, 2.77mm, 2.87mm, 2.90mm, 2.97mm, 3.05mm, 3.18mm, 3.38mm, 3.40mm, 3.56mm, 3.68mm, 3.73mm, 3.76mm, 3.91mm, 3.96mm, 4.19mm, 4.55mm, 4.57mm, 4.78mm, 4.85mm, 5.08mm, 5.16mm, 5.49mm, 5.54mm, 5.56mm, 5.74mm, 6.02mm, 6.35mm, 6.55m, 7.01mm, 7.04mm, 7.11mm, 7.14mm, 7.47mm, 7.62mm, 7.8mm, 7.82mm, 7.92mm, 8.08mm, 8.18mm, 8.38mm, 8.56mm, 8.74mm, 9.09mm, 9.27mm, 9.53mm, 9.70mm, 10.15mm, 10.31mm, 10.97mm, 11.07mm, 11.13mm, 12.7mm, 13.49mm, 14.02mm, 14.27mm, 15.09mm, 15.24mm, 15.88m, 16.66mm, 17.12mm, 17.48mm, 18.26mm, 19.05mm, 20.62mm, 21.44mm, 21.95mm, 22.23mm, 23.01mm, 23.83mm, 24.61mm, 25.40mm, 26.19mm, 27.79mm, 28.58mm, 29.36mm, 30.96mm, 31.75mm, 32.54mm, 33.32mm, 34.93mm, 35.71mm, 36.53mm, 38.10mm, 38.89mm, 39.67mm, 40.49mm, 41.28mm, 44.45mm, 45.24mm, 46.02mm, 47.63mm, 50.01mm, 52.37mm, 53.98mm, 59.54mm.

Materials

Carbon Steel

ASTM A234 WPB

ASTM A420 WPL3, ASTM A420 WPL6

ASTM A860 WPHY 42, ASTM A860 WPHY52, ASTM A860 WPHY60, ASTM A860 WPHY65, ASTM A860 WPHY70

ASTM A105, ASTM A105N

ASTM A350 LF1, ASTM A350 LF2 CL1, ASTM A350 LF2 CL2, ASTM A350 LF3 CL1, ASTM A350 LF3 CL2

ASTM A694 F42, ASTM A694 F46, ASTM A694 F48, ASTM A694 F50, ASTM A694 F52, ASTM A694 F60, ASTM A694 F65, ASTM A694 F70

Stainless Steel

ASTM A403 WP304/304L, ASTM A403 WP316/316L, ASTM A403 WP321, ASTM A403 WP347

ASTM A182 F304, ASTM A182 F304L, ASTM A182 F316, ASTM A182 F316L, ASTM A182 F316H, ASTM A182 F310, ASTM A182 F321

Alloy Steel

ASTM A234 WP5, ASTM A234 WP9, ASTM A234 WP11, ASTM A234 WP12, ASTM A234 WP22, ASTM A234 WP91

ASTM A182 F1, ASTM A182 F5, ASTM A182 F9, ASTM A182 F11, ASTM A182 F22, ASTM A182 F91

Duplex Steel

ASTM A815 UNS S31803, ASTM A815 UNS S32750, ASTM A815 UNS S32760

ASTM A182 F51, UNS S31803, ASTM A182 F53, UNS S32750, ASTM A182 F55, UNS S32760

Ends

Plain end, Beveled end, SW end and NPT end

Standards

ANSI B16.9, ANSI B16.28, ANSI B16.49, MSS SP 75, MSS SP 43, ANSI B16.11, MSS SP 83 and MSS SP 97

Applications

Used for oil, crude oil, petroleum, natural gas, water, offshore, power, pipe projects, etc.

Pipe fittings are auxiliary accessories of the pipeline system, which help the pipeline to achieve functions of connecting, diverting, and adjusting the flow. Qishine provides steel pipe fittings for pipelines. According to different processes, steel pipe fittings are mainly divided into flanges, threaded pipe fittings, and butt-welding pipe fittings. For butt-welded pipe fittings, it is necessary to indicate whether they are welded or seamless when purchasing.

Butt welded fitting

45 deg. short radius elbow, 90 deg. short radius elbow, 180 deg. short radius elbow, 45 deg. elbow, 90 deg. elbow, 180 deg. elbow

Equal tee, reducing tee

Concentric reducer, eccentric reducer

Cross, equal cross, reducing cross

Half coupling, full coupling, reducing coupling

Cap, bend, barred tee, stub end, weldolet, sockolet, threadolet, hex. nipple, swage nipple, union, boss, hex. head bushing, plug, etc.

Processing

Butt welding and forging

Sizes

DN15, DN20, DN25, DN32, DN40, DN50, DN65, DN80, DN90, DN100, DN125,DN150, DN200, DN250, DN300, DN350, DN400, DN450, DN500, DN550, DN600, DN650, DN700, DN750, DN800, DN850, DN900, DN950, DN1000, DN1050, DN1100, DN1150, DN1200

OD21.3 mm, OD26.7 mm, OD33.4 mm, OD42.2 mm, OD48.3 mm, OD60.3 mm, OD73 mm, OD88.9 mm, OD101.6 mm, OD114.3 mm, OD141.3 mm, OD168.3 mm, OD219.1 mm, OD273.1 mm, OD323.9 mm, OD355.6 mm, OD406.4 mm, OD457.2 mm, OD508 mm, OD559 mm, OD610 mm, OD660 mm, OD711 mm, OD762 mm, OD813 mm, OD864 mm, OD914 mm, OD965 mm, OD1016 mm, OD1067 mm, OD1118 mm, OD1168 mm, OD1219 mm

1/2 Inch, 0.5 Inch, 3/4 Inch, 0.75 Inch, 1 Inch, 1-1/4 Inch, 1.25 Inch, 1-1/2 Inch, 1.5 Inch, 2 Inch, 2-1/2 Inch, 2.5 Inch, 3 Inch, 3-1/2 Inch, 3.5 Inch, 4 Inch, 5 Inch, 6 Inch, 8 Inch, 10 Inch, 12 Inch, 14 Inch, 16 Inch, 18 Inch, 20 Inch, 22 Inch, 24 Inch, 26 Inch, 28 Inch, 30 Inch, 32 Inch, 34 Inch, 36 Inch, 38 Inch, 40 Inch, 42 Inch, 44 Inch, 46 Inch, 48 Inch

Schedule or Wall Thickness

SCH 5, SCH 5S, SCH 10, SCH 20, SCH 30, SCH STD, SCH 40, SCH 60, SCH XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, SCH XXS

1.65mm, 2.11mm,2.41mm, 2.77mm, 2.87mm, 2.90mm, 2.97mm, 3.05mm, 3.18mm, 3.38mm, 3.40mm, 3.56mm, 3.68mm, 3.73mm, 3.76mm, 3.91mm, 3.96mm, 4.19mm, 4.55mm, 4.57mm, 4.78mm, 4.85mm, 5.08mm, 5.16mm, 5.49mm, 5.54mm, 5.56mm, 5.74mm, 6.02mm, 6.35mm, 6.55m, 7.01mm, 7.04mm, 7.11mm, 7.14mm, 7.47mm, 7.62mm, 7.8mm, 7.82mm, 7.92mm, 8.08mm, 8.18mm, 8.38mm, 8.56mm, 8.74mm, 9.09mm, 9.27mm, 9.53mm, 9.70mm, 10.15mm, 10.31mm, 10.97mm, 11.07mm, 11.13mm, 12.7mm, 13.49mm, 14.02mm, 14.27mm, 15.09mm, 15.24mm, 15.88m, 16.66mm, 17.12mm, 17.48mm, 18.26mm, 19.05mm, 20.62mm, 21.44mm, 21.95mm, 22.23mm, 23.01mm, 23.83mm, 24.61mm, 25.40mm, 26.19mm, 27.79mm, 28.58mm, 29.36mm, 30.96mm, 31.75mm, 32.54mm, 33.32mm, 34.93mm, 35.71mm, 36.53mm, 38.10mm, 38.89mm, 39.67mm, 40.49mm, 41.28mm, 44.45mm, 45.24mm, 46.02mm, 47.63mm, 50.01mm, 52.37mm, 53.98mm, 59.54mm.

Materials

Carbon Steel

ASTM A234 WPB

ASTM A420 WPL3, ASTM A420 WPL6

ASTM A860 WPHY 42, ASTM A860 WPHY52, ASTM A860 WPHY60, ASTM A860 WPHY65, ASTM A860 WPHY70

ASTM A105, ASTM A105N

ASTM A350 LF1, ASTM A350 LF2 CL1, ASTM A350 LF2 CL2, ASTM A350 LF3 CL1, ASTM A350 LF3 CL2

ASTM A694 F42, ASTM A694 F46, ASTM A694 F48, ASTM A694 F50, ASTM A694 F52, ASTM A694 F60, ASTM A694 F65, ASTM A694 F70

Stainless Steel

ASTM A403 WP304/304L, ASTM A403 WP316/316L, ASTM A403 WP321, ASTM A403 WP347

ASTM A182 F304, ASTM A182 F304L, ASTM A182 F316, ASTM A182 F316L, ASTM A182 F316H, ASTM A182 F310, ASTM A182 F321

Alloy Steel

ASTM A234 WP5, ASTM A234 WP9, ASTM A234 WP11, ASTM A234 WP12, ASTM A234 WP22, ASTM A234 WP91

ASTM A182 F1, ASTM A182 F5, ASTM A182 F9, ASTM A182 F11, ASTM A182 F22, ASTM A182 F91

Duplex Steel

ASTM A815 UNS S31803, ASTM A815 UNS S32750, ASTM A815 UNS S32760

ASTM A182 F51, UNS S31803, ASTM A182 F53, UNS S32750, ASTM A182 F55, UNS S32760

Ends

Plain end, Beveled end, SW end and NPT end

Standards

ANSI B16.9, ANSI B16.28, ANSI B16.49, MSS SP 75, MSS SP 43, ANSI B16.11, MSS SP 83 and MSS SP 97

Applications

Used for oil, crude oil, petroleum, natural gas, water, offshore, power, pipe projects, etc.

Pipe fittings are auxiliary accessories of the pipeline system, which help the pipeline to achieve functions of connecting, diverting, and adjusting the flow. Qishine provides steel pipe fittings for pipelines. According to different processes, steel pipe fittings are mainly divided into flanges, threaded pipe fittings, and butt-welding pipe fittings. For butt-welded pipe fittings, it is necessary to indicate whether they are welded or seamless when purchasing.