Nickel 200 Hex Head Bolt: Versatile Applications and Superior Performance

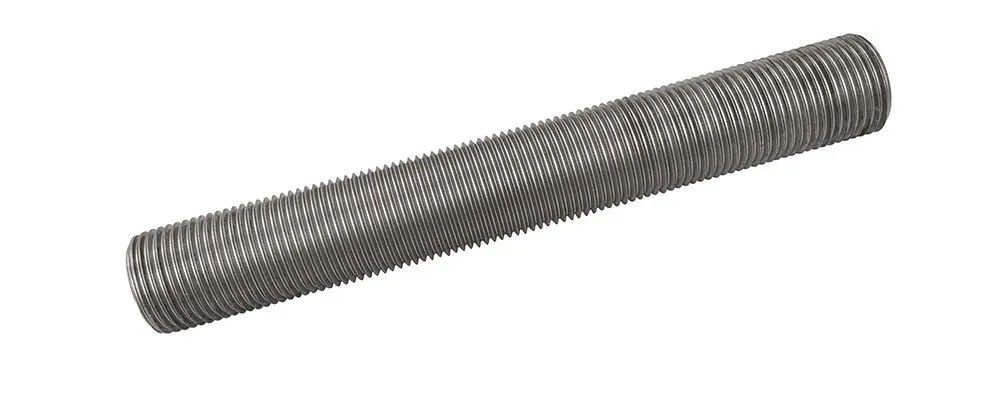

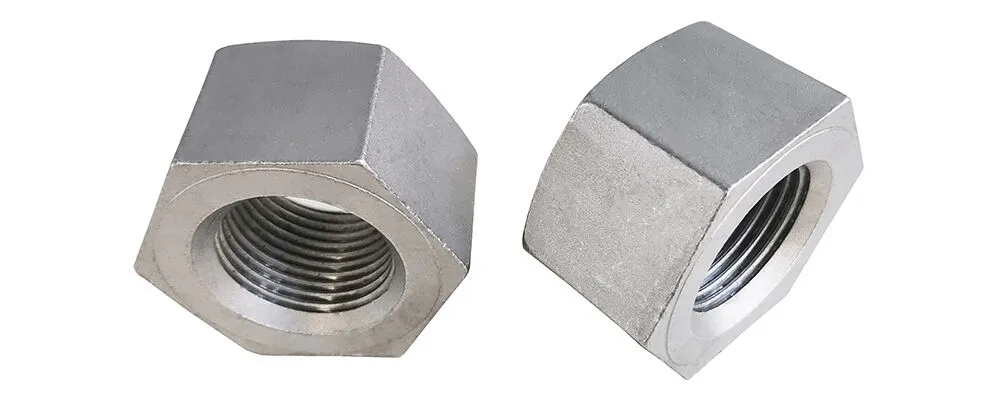

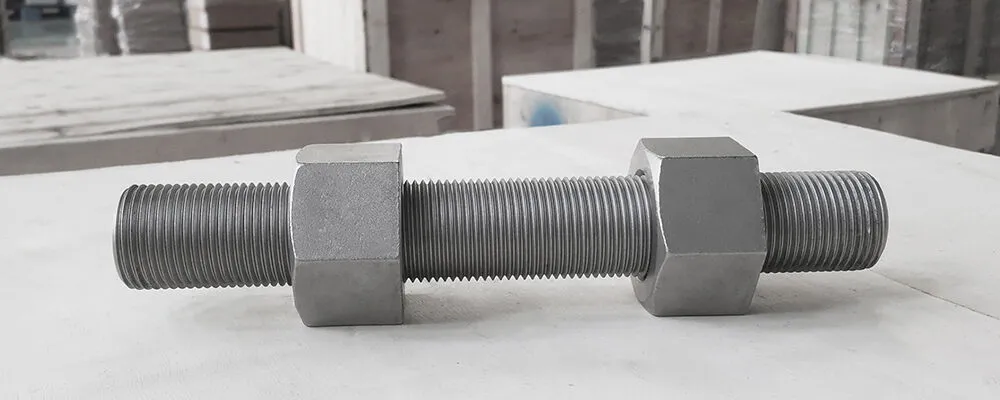

Introduction Nickel 200 hex head bolts are a crucial component in various industries due to their exceptional properties and versatility. With a range of sizes from M8 to M64 and lengths from 30 to 800 mm, these bolts, also known as W.Nr.2.4060 bolts, offer a wide array of applications across different sectors. In this article, we will delve into the hot topic related to nickel 200 hex head bolts, exploring their unique features, benefits, and real-world examples of how they are utilized in industrial...